Latest News

NEWS

14/01/26

NEWS

09/12/25

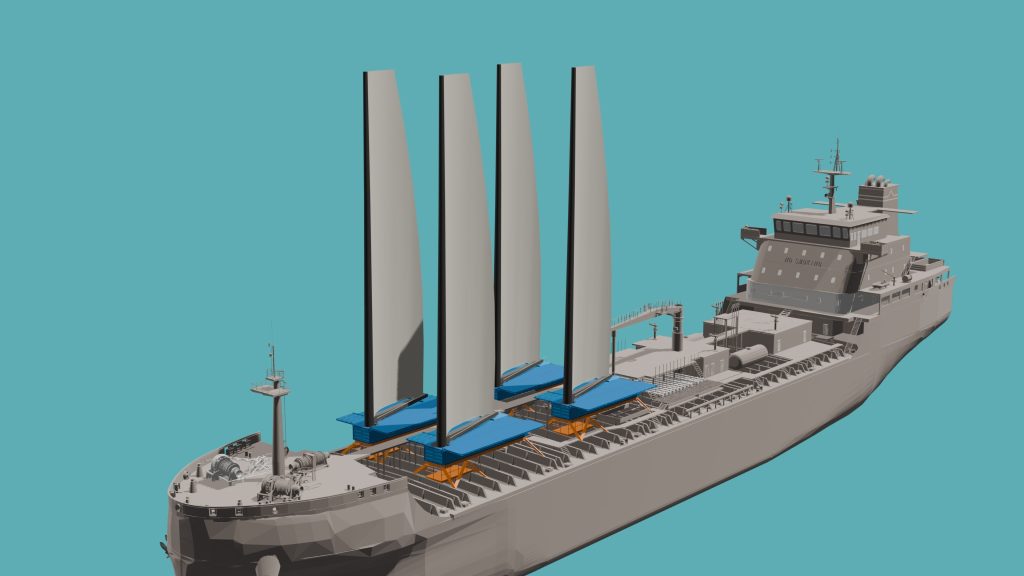

lomarlabs supports Advanced Wing Systems to innovate containerised wing sails

Read More

NEWS

18/11/25

BlueNose awarded £350,000 UK Government funding to advance aerodynamic innovation in shipping

Read More

NEWS

03/11/25

Newlight Completes RINA FAT for Hydrogen Retrofit on Two- and Four-Stroke Main Engines

Read More

NEWS

02/09/25

Mythos AI and lomarlabs Launch Next-Gen Bridge Intelligence Pilot Aboard CB Pacific

Read More

NEWS

28/08/25

Driving Decarbonisation Together: lomarlabs Leads Commercialisation Work in Seabound Consortium

Read More

NEWS

20/08/25

Seabound Secures £1.1 Million Grant from UK Government

Read More

NEWS

17/06/25

Mapping the Capital Current: Inside the First Oslo Maritime Venture Financing Forum

Read More

NEWS

28/05/25